Shop By Category

Related Links

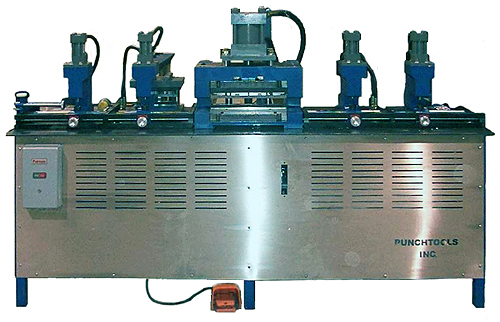

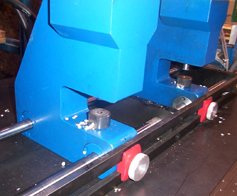

Gang punches dedicated to processing one product line are becoming more common as companies streamline production and reduce inventory levels. The Hydraulic Centre Station Gang Buster addresses these issues and more, with benefits such as portability, ease of hookup, and a variable production range.

Portability

Take the machine to the extrusion — not extrusion to the machine. This flexibility enhances plant design and layout. The unit is highly portable with the following features:

- Forklift-moveable with balanced load and a solid, welded 2” square steel tube frame.

- Low centre of gravity for stability during movement.

- Relatively lightweight — 1,000 lb versus a 10,000 lb press brake with similar tonnage but a top-heavy design.

Ease of Hookup and Use

- 240-volt connection plug for convenient hookup to cable drops around the plant.

- No need for hard wiring or an electrician every time it's moved.

- Tethered foot pedal so operator has freedom to locate efficiently for loading and unloading.

Streamlined Operations

Reduce inventory levels and accommodate a variable production range — this is where the unit proves it’s worth.

- Previously, inventory levels required a set of parts across various lengths, leading to a finished inventory of approximately 20 combinations.

- After implementing the Hydraulic Centre Station Gang Buster, finished goods could be produced to order, virtually eliminating finished goods inventory and freeing up space used for other activities.

- Only raw material inventory needs management, leading to significant inventory reduction.

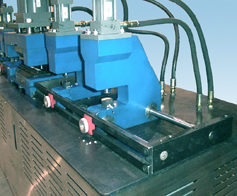

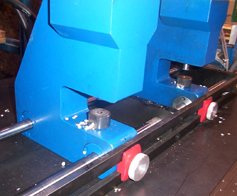

- The Gang Buster’s variable production is built around part geometry: the large center punch station is fixed, and the outer mounting holes are referenced from it.

- Within minutes, the operator can adjust the outer mounting holes to preset pitch stops and switch to new finished products on demand, achieving enhanced manufacturing flexibility—a key to meeting productivity goals.

Machine Specifications

- Hydraulic power pack: 240/480-volts (other voltages available upon request).

- Footprint: 120”L x 24”W x 32”H to table top/working height (approximately 60” overall).

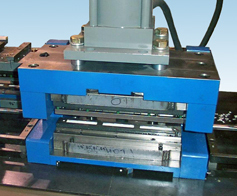

- Centre station: Fixed astragal punch, 35 tons.

- Outer stations: Four variable pitch stations at 5 tons each, with hose hydraulic connections.

- Punches and dies: Off-the-shelf, common components.

- Production rate: Punch cycle time of 5 seconds.

ABOUT US

OUR SERVICES

TOOL & DIE MFG

OUR PRODUCTS

INDUSTRY LIBRARY

PTI Punch Tools Inc.

11-211 Schoolhouse Street

Coquitlam, BC, Canada. V3K4X9

Telephone

604-521-6444

1-800-668-4996

11-211 Schoolhouse Street

Coquitlam, BC, Canada. V3K4X9

Telephone

604-521-6444

1-800-668-4996