Shop By Category

Related Links

EDM Drill

EDM (Electrical Discharge Machining) Drilling

EDM (Electrical discharge machining) drilling, also known as hole poppers, small hole drilling, fast hole drilling, and start hole drilling, is the process of drilling holes on an electrically conductive surface with an electrode tube, typically brass. The tube is used to channel the electricity and allows for different sized holes.

The Joemars Super Drill EDM JM325D is an EDM drill machine that we use here at Punch Tools, featuring sparking circuits to enhance machining speed, high accuracy, lower wear, and excellent flushing power.

This process is typically used to create a start hole for a Wire EDM Machine.

How Does It Work?

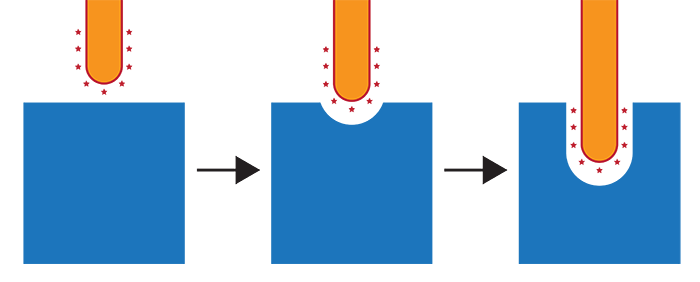

An EDM drill works by creating a spark between the workpiece and the electrode tube as it begins to drill into it. The spark from the drill generates an intense amount of heat and jumps across the gap between the two, eroding the workpiece. This unit is specially designed for drilling hard materials, such as hardened tool steel or alloys, tungsten carbide. The holes range in size from 0.012" (0.3 mm) to 0.118" (3.0 mm). The smallest holes cannot be made with a traditional drill bit.

Punch Tools is one of the few places that does Wire EDM or Drill EDM Machining in Vancouver BC.

What can it do?

This manufacturing process is the perfect method to use when you are looking to add small holes to a piece, even one that has inclined faces or is in a difficult position.

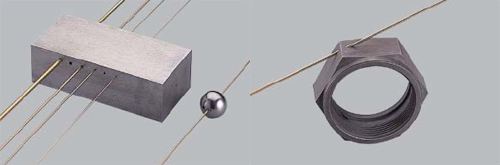

An EDM drill is capable of drilling holes of various sizes and in inclined faces.

The picture shows M2.2 bolts being meticulously drilled by an EDM machine. This process uses 0.65 mm thick brass wire to create 0.70 mm diameter holes precisely centered in the bolts, demonstrating the drill's capacity for accurate and detailed work.

So why use EDM Drilling?

EDM drilling is a manufacturing process that gives accurate results. It allows for clean and deep holes to be drilled from an array of sizes that would be almost impossible to do with conventional machining tools. Much like using Wire EDM, EDM drilling also eliminates human error so each drill comes out perfect.

ABOUT US

OUR SERVICES

TOOL & DIE MFG

OUR PRODUCTS

INDUSTRY LIBRARY

11-211 Schoolhouse Street

Coquitlam, BC, Canada. V3K4X9

Telephone

604-521-6444

1-800-668-4996