Shop By Category

Related Links

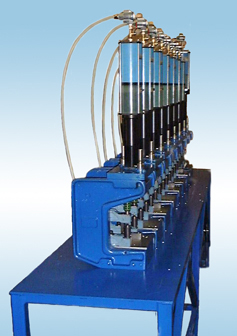

Air/oil power cylinders offer an excellent alternative to traditional power sources for punching. The air/oil cylinder magnifies shop air 200 times to deliver sufficient power for light duty punching applications that a standard air cylinder could not obtain unless the diameter was huge.

Air/oil gang punches are great for light gauge extrusion and offer a low-maintenance solution for production machines. Only a shop air hookup is required — no hydraulic oil — few moving parts to wear.

Portability

Take the machine to the extrusion not extrusion to the machine. This allows greater flexibility in plant design and layout. First off the unit is very portable with the following features:

- Forklift moveable with balanced load and solid welded 2” square steel tube frame tube.

- Low center of gravity for stability during movement.

- Relatively light weight — 1000 lb versus a press brake with sufficient tonnage weighing 10,000 lb and top heavy.

- The Air/Oil Gang Buster could be relocated across the plant in a few minutes and be punching in a different department right away. Machine utilization goes through the roof and bottlenecks are eliminated.

Streamline Operations

Reduce equipment on the floor space and increase productivity — this is where the unit proves its worth.

- After the 8-station Air/Oil Gang Buster was introduced finished goods were made to order.

- Finished goods inventory was virtually eliminated and the space was used for other activities.

- Only raw material inventory needs to be managed — a significant inventory reduction.

- C-frame-based tooling is a low-cost solution with flexibility and readily available parts.

- This manufacturing flexibility was the key to meeting the productivity goals.

Ease of Hookup and Use

- Air connection hookup to shop air system around the plant.

- No need for hard wiring and a qualified electrician every time a move is needed.

- Tethered foot pedal so the operator has the freedom to locate efficiently for loading and unloading.

Machine Specifications

- Shop air connection only required for operation.

- Foot print 120”L x 24”W x 32”H to table top/working height (approximately 84” overall).

- 16 fixed pitch stations at 3 tons each.

- Quickly connect air hose connections.

•Punches and dies — off the shelf common components.

•Production rate — punch cycle time of 5 seconds.

PTI Punch Tools Inc

11-211 Schoolhouse Street

Coquitlam, BC, Canada. V3K4X9

604-521-6444 | 1-800-668-4996

© 2024 PTI Punch Tools Inc. All rights reseved

Powered by Digit Art Designs Ltd.