Shop By Category

Related Links

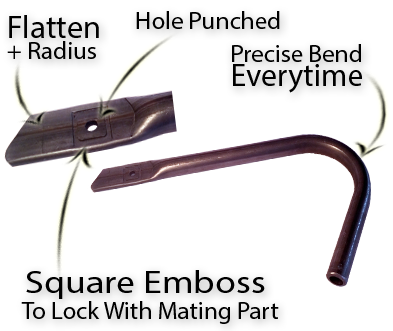

Punch Tools leverages its extensive industry knowledge in metal tube bending across many projects. This expertise has led to:

- Several innovations in tooling and design,

- Significant reductions in cycle times, and

- Improving product quality for finished stamped and bent metal tubing.

The production of tube components is a complex, multi-staged process that requires specialized knowledge and control to ensure consistent results. Our experience includes high-volume punching of metal tubing for various applications, such as the Bike Barn motorcycle cover.

Industry Knowledge Application

The video below explores how we approached an unusual tube bending challenge.

For professional examples of our metal tube bending in action using galvanized steel, please visit our Project Partner: The Bike Barn or explore our Production Hardware section.

ABOUT US

OUR SERVICES

TOOL & DIE MFG

OUR PRODUCTS

INDUSTRY LIBRARY

PTI Punch Tools Inc.

11-211 Schoolhouse Street

Coquitlam, BC, Canada. V3K4X9

Telephone

604-521-6444

1-800-668-4996

11-211 Schoolhouse Street

Coquitlam, BC, Canada. V3K4X9

Telephone

604-521-6444

1-800-668-4996