Shop By Category

Related Links

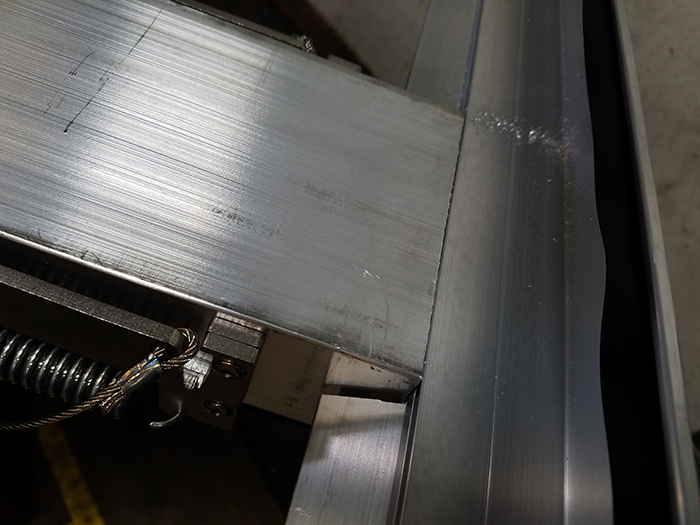

Fast, Flush, and Fabrication-Ready: The Precision Extrusion Notcher

Welding Ready

Effortlessly remove sections of an extrusion with surgical ease, leaving a perfectly flush surface optimized for immediate welding.

Dual-Force Stoppers

Features versatile front stoppers at 10lbs and 30lbs to accommodate different extrusion profiles and wall thicknesses.

Operator Efficiency

Ergonomic front-access loading and a secure brace system allow for rapid placement and consistent accuracy across large batches.

Revolutionizing the Notching Process

Where once a CNC Mill was required to meticulously carve out notches, our specialized system streamlines the task. No complex programming or tool changes required—just lock the extrusion, press a button, and achieve CNC-level precision in seconds.

Elevate Your Workflow Levels

Achieve unprecedented levels of precision and ease in your extrusion fabrication.

Request a Quote & Technical Specs

ABOUT US

OUR SERVICES

TOOL & DIE MFG

OUR PRODUCTS

INDUSTRY LIBRARY

11-211 Schoolhouse Street

Coquitlam, BC, Canada. V3K4X9

Telephone

604-521-6444

1-800-668-4996