Shop By Category

Related Links

Our Punch Tool's custom curtain wall punch press are designed to save you time on installation and create identical punches for a clean and efficient production. Our custom standalone hydraulic punching presses allow you to place and punch countersunk holes or deadbolt knockouts on all aluminum curtain wall extrusions for perfect curtain wall mounting to fit your design needs.

Features

- Identical punches every time for clean and efficient production

- Saves on installation time

- Able to countersink holes in difficult locations

- Typically in hydraulic stand alone stations

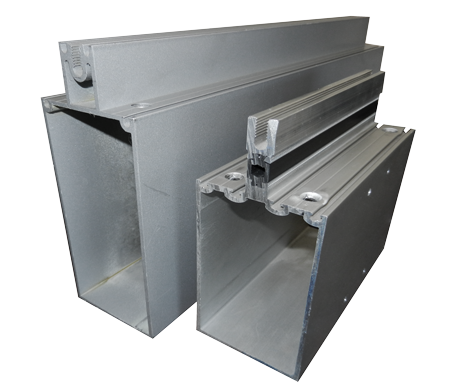

Here we have two examples of our curtain wall mullion mounts, made out of aircraft grade aluminum extrusion, with multiple countersunk mounting holes punched in difficult locations between screw chasers. The smaller aluminum extrusion mullion had the challenge of needing to place the counter sunk holes in between two screw chaser channels. The design problem was solved by using a two part punching press operation to first punch a smaller hole in place and then countersink them. This stopped the area surrounding the screw chasers from deforming in any way leaving the piece structurally sound.

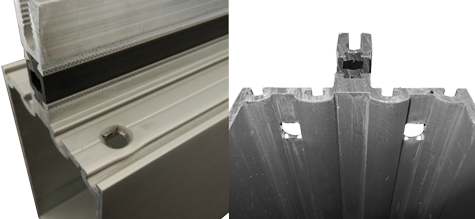

Above: Alternate views of the smaller aluminum curtain wall industry extrusion highlighting the countersunk top punched holes and their difficult placement in between screw chasers.

Above: A side view of the smaller aluminum curtain wall extrusion highlighting the punched side mounting holes.

Alternate Model 1

The larger model had a similar design challenge placing the countersunk rounds beside screw chasers so the same method as with the smaller extrusion was used of a hole punch followed by a countersinking.

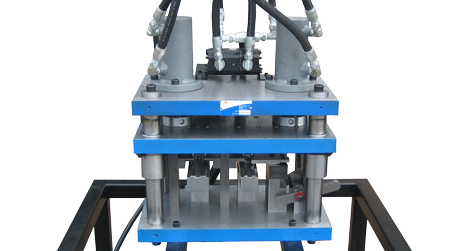

This Punch Tools standalone hydraulic Punch Press is responsible for a two step punching and countersinking process that creates the countersunk punches in the above curtain wall aluminum extrusions.

Alternate Model 2

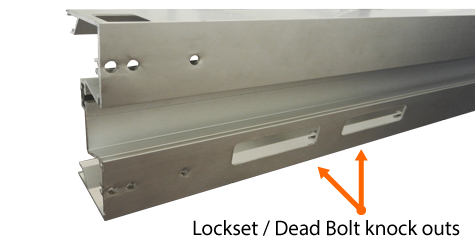

A different style of aluminum curtain wall mounting extrusion with multiple hole punches perpendicular through screw chasers and lockset / dead bolt knockouts places on multiple surfaces of the piece.

Images above: Various views of the lockset and deadbolt knockouts.

ABOUT US

OUR SERVICES

TOOL & DIE MFG

OUR PRODUCTS

INDUSTRY LIBRARY

11-211 Schoolhouse Street

Coquitlam, BC, Canada. V3K4X9

Telephone

604-521-6444

1-800-668-4996