Shop By Category

Related Links

A stamping die is a specialized, one-of-a-kind precision tool used to cut and form sheet metal into a specific shape or profile. Stamping dies are typically designed with CAD software (such as SolidWorks®) to ensure precision. Skilled diemakers then craft these dies, which are then mounted in presses to produce sheet metal parts.

Build your own custom tooling with us to meet your specific requirements. Our in-house precision metal stamping tooling guarantees maximum durability and reliability.

1. Cut To Length Dies

Most popular, affordable, and quickest methods of turning large metal coils into manageable workpieces.

As metal strips are fed through the tool, they are cut to precise specifications every time. For even greater automation, a feeder can be attached to the cut-to-length

| Cut To Length Tools Explained: Step-by-Step Illustration | |

|

1) The metal is fed through the machine.  |

2) The metal is sliced with a shear, creating radius edges.  |

|

3) The sharp corners are subtly contoured (or "broken") for longevity, safety, and optimal part performance.  |

4) This method can be combined with punching, bending, progressive stamping, and other techniques to create complex metal shapes. See more →  |

2. Form Dies

Form tools stretch metal to create complex shapes. As the press pushes down on a metal sheet around a form, the metal retains the desired shape. Although initial development can be extensive, once any issues (like wrinkles) are resolved, the proper form is achieved every time.

Forming tools function as dies that bend, stretch, or otherwise shape sheet metal to create form features such as louvers, lances, flanges, and ribs.

3. Compound Dies

Compound tools is ideal for creating parts with tight tolerances on multiple related edges, which would be costly to achieve with a progressive tool—especially for low-volume parts where a progressive tool may be prohibitively expensive.

Compound stamping tooling performs multiple cuts, punches, and bends in a single stroke rather than multiple strokes.

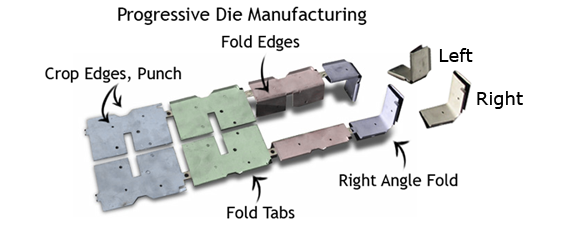

4. Progressive Dies

Progressive tooling is highly efficient for producing intricate multi-stage parts. This type of tool significantly boosts productivity and reduces production run times for large batches, as it can perform various actions such as cutting, coining, punching, bending, lancing, shaving, extruding, drawing, and embossing.

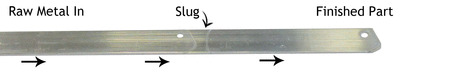

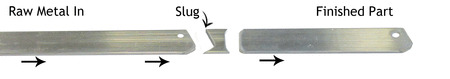

The image below illustrates how metal are fed through the tool in progressive stages to produce a fully finished pair of parts.

5. Blanking Dies / Piercing Dies

Blanking dies create shapes or contours by shearing or cutting them out of sheet or strip stock. For larger production runs, blanking is often done in multiple dies and combined with other operations, such as piercing and forming, in combination and progressive dies.

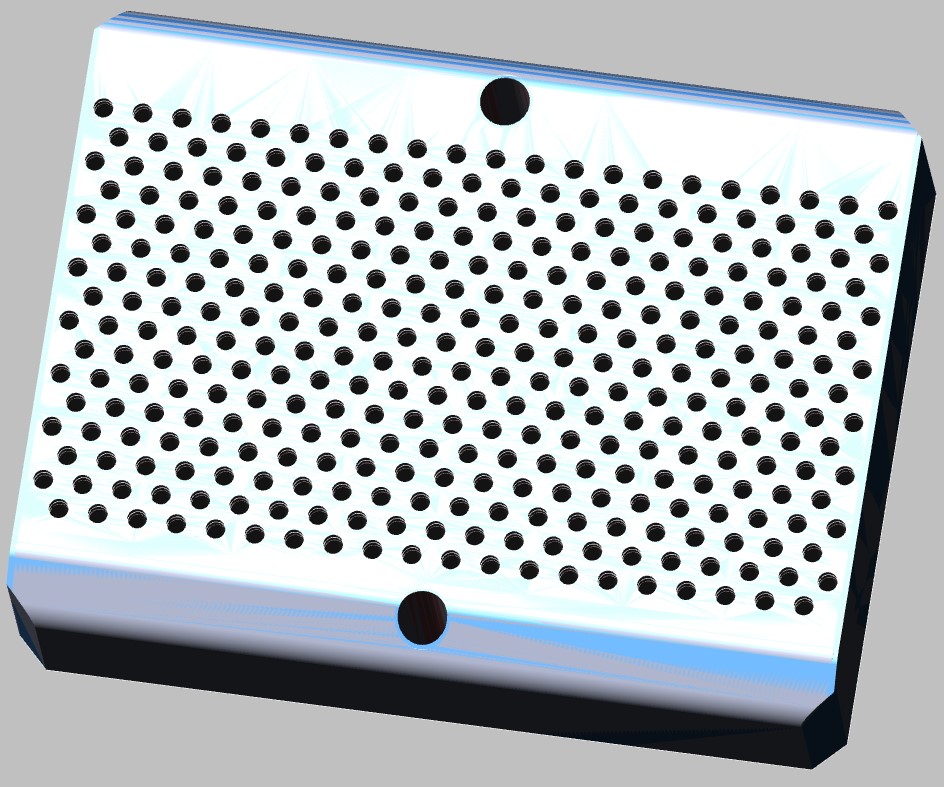

6. Perforating Dies

Perforating dies punch patterns into flat steel sheets, creating closely spaced holes in thin materials for air or liquid flow. We offer custom perforated metal products, including round, square, slotted, decorative, and bespoke designs.

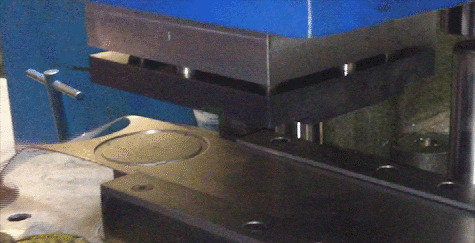

Watch our Progressive Dies in Action in the Video Gallery Below.

ABOUT US

OUR SERVICES

TOOL & DIE MFG

OUR PRODUCTS

INDUSTRY LIBRARY

11-211 Schoolhouse Street

Coquitlam, BC, Canada. V3K4X9

Telephone

604-521-6444

1-800-668-4996