Shop By Category

Related Links

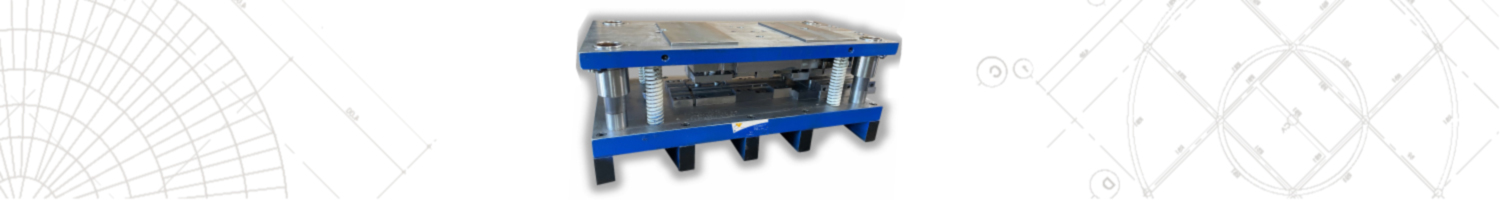

Tooling is the backbone of Metal Stamping Industry, and Punch Tools has the knowledge and expertise to keep your tooling and machinery in top condition, ensuring minimal downtime and peak performance.

Our Services:

- Tool Repair Expertise: Quick turnaround on repairs to minimize downtime.

- Preventative Maintenance: Regular maintenance to prevent issues and extend the life of your equipment.

- Revisions and Rebuilding: Updating and rebuilding components to restore optimal performance.

- Emergency Support: Immediate assistance for urgent repairs and troubleshooting.

Tool Repair Expertise

Our talented team in the Tool and Die Department collectively brings over 150+ years of experience to each repair and troubleshooting task. Tooling is an art, and our craftsmen provide the hands-on creativity to solve a variety of production-related challenges.

Quick Turnaround: Revisions and Rebuilding

Downtime is lost production but our customers know we can get them back in business fast. To help this process and reduce delays we maintain an extensive inventory of standard tooling components including: pins, bushings and die springs.

Preventative Maintenance

-

Schedule Maintenance: Regular inspections, servicing, adjustments, and replacements to prevent breakdowns, extending equipment life.

-

Sharpening: Precision sharpening for tools, dies, and parts, restoring optimal cutting edges for efficient operation.

-

Repair of components: We specialize in repairing and rebuilding components to restore them to their optimal condition. Our services address issues such as wear and damage, ensuring your equipment operates reliably and efficiently.

-

Replacement of parts: Access to high-quality replacement parts to keep machinery running smoothly.

-

Troubleshooting: Diagnosing issues and providing effective solutions to reduce downtime.

Emergency Support

Tel: 1.800.668.4996

Email: sales@punchtools.com

Let Punch Tools handle your Tooling Maintenance Program, so you can focus on filling your machine uptime.

ABOUT US

OUR SERVICES

TOOL & DIE MFG

OUR PRODUCTS

INDUSTRY LIBRARY

11-211 Schoolhouse Street

Coquitlam, BC, Canada. V3K4X9

Telephone

604-521-6444

1-800-668-4996