Shop By Category

Related Links

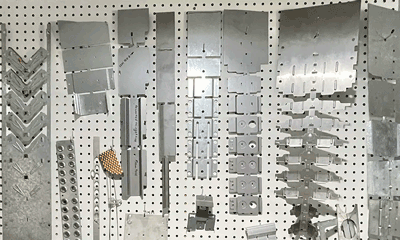

Tool up and enhance your efficiency and productivity with Punch Tools’ in-house tool and die manufacturing.

Manufacturing Services

- Full Production Service:

From design and prototyping to completed precision metal stamping. - Metal Stamping Production:

Heavy and high-speed stamping, laser cutting, assembly, and integration. - Custom High-Tonnage Die Sets:

Bespoke design and manufacture of heavy-duty press die sets. - Repair & Maintenance:

Expert services to minimize downtime and ensure optimal tool performance. - Secondary Services:

Post-processing, plating, and finishing handling. Email us for details.

Our tool and die shop handles all your metal stamping needs, from simple perforation and shearing to complex progressive tooling that combines forming, embossing, punching, and shearing.

Punch Tools’ experienced toolmakers not only create new tools but also service existing ones, reducing downtime. We can establish a preventative maintenance program to give you total peace of mind.

We add value through our extensive experience, offering innovative solutions that provide you with a new competitive advantage.

ABOUT US

OUR SERVICES

TOOL & DIE MFG

OUR PRODUCTS

INDUSTRY LIBRARY

PTI Punch Tools Inc.

11-211 Schoolhouse Street

Coquitlam, BC, Canada. V3K4X9

Telephone

604-521-6444

1-800-668-4996

11-211 Schoolhouse Street

Coquitlam, BC, Canada. V3K4X9

Telephone

604-521-6444

1-800-668-4996