Shop By Category

Related Links

The Hydraulic Press Gangbuster revolutionizes the process, replacing the outdated method of using CNC mills to cut holes one at a time. With its 6 stations, it allows you to punch out 36 holes simultaneously with just the press of a button—or two.

The Hydraulic press Gangbuster by Punch Tools is a revolutionary piece of equipment. It is hydraulically operated and can extrude multiple sections of the sheet metal at once.

This Gangbuster Model features:

- A modular construction for easy maintenance.

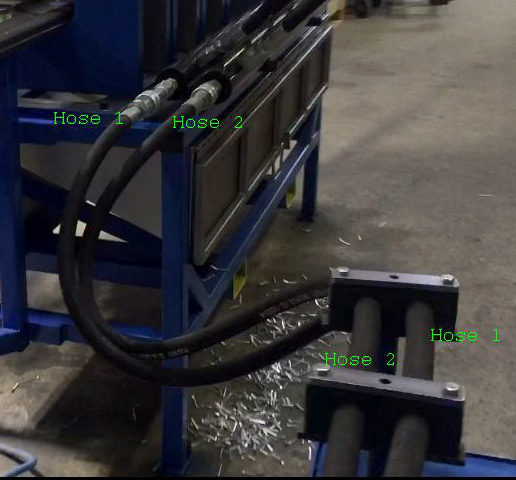

- A hydraulic oil distribution manifold.

- Highly accurate pressure gauges.

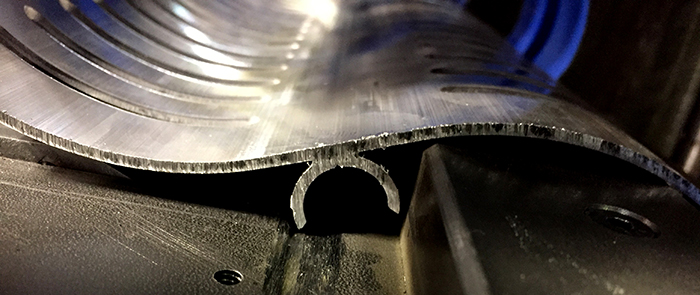

- Slug catcher.

- Six individual punch heads.

- ON/OFF lever on each punch head.

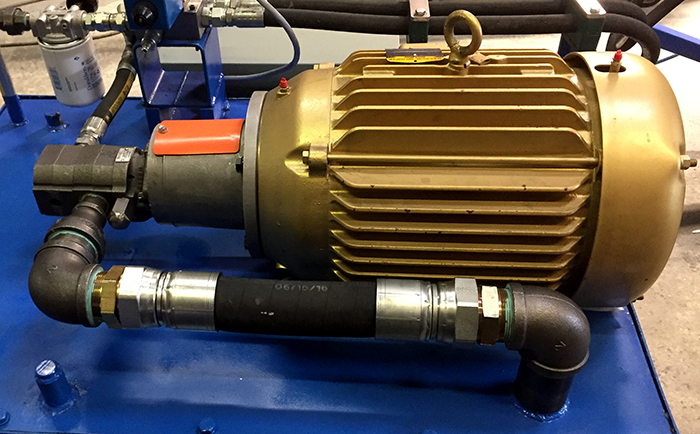

- High flow geared pump with 20 horse power motor.

- Pilot valve

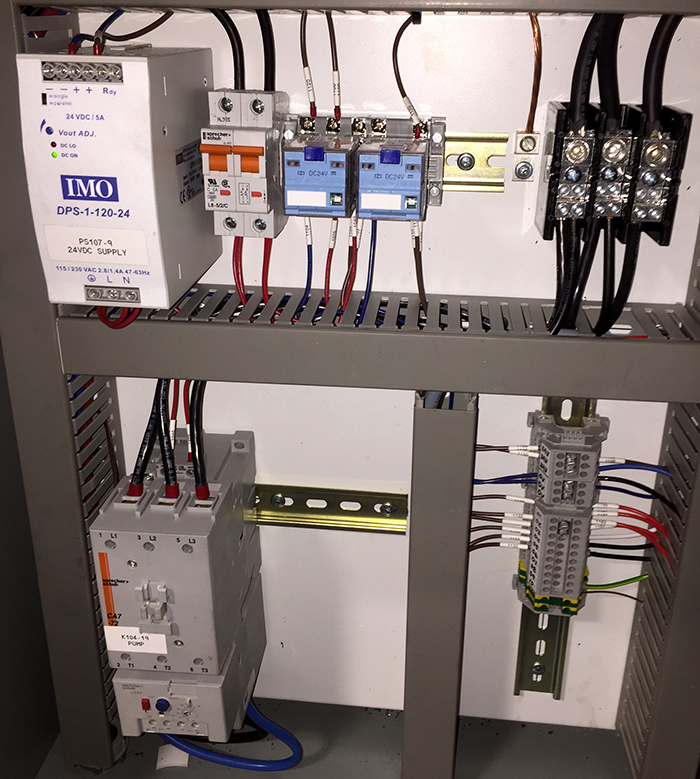

- Control panel & electrical schematic.

- Automatic retraction safety feature.

- Pitch Stopper.

- Distance stopper distances of: 6,7,8,9,10,12ft.

How it works:

- Operation: Punch stations are connected to a pressure tube that transmits compressive force to punch extrusions from the metal. The electrical cabinet houses the power supply, relays, and pump motor.

- Setup: Adjust the back stopper to the desired sheet metal length (6ft, 7ft, 8ft, 9ft, 10ft, or 12ft) before starting.

- Control: Use the two-handed button control—both buttons must be pressed simultaneously to begin the operation.

- Process: After the initial punch, move the sheet along the track. Lock the first hole with the pitch stopper and repeat the punching process, securing every third hole with the pitch stopper until the sheet is complete.

Why use it:

- Efficiency: Eliminates the need for CNC machines by allowing up to 36 extrusions to be punched out simultaneously, reducing processing time and energy use.

- Safety: Automatic retraction safety feature retracts the punch heads when one or both operation buttons are released, ensuring the operator’s attention and acting as an emergency switch.

- Precision: Pitch stopper at the end of the track ensures consistent and even spacing between punches.

- Control: Each punch station has an on/off lever at the top to avoid accidental punches in unwanted areas or at the edges of the sheet metal.

ABOUT US

OUR SERVICES

TOOL & DIE MFG

OUR PRODUCTS

INDUSTRY LIBRARY

PTI Punch Tools Inc.

11-211 Schoolhouse Street

Coquitlam, BC, Canada. V3K4X9

Telephone

604-521-6444

1-800-668-4996

11-211 Schoolhouse Street

Coquitlam, BC, Canada. V3K4X9

Telephone

604-521-6444

1-800-668-4996