Shop By Category

Related Links

HVAC & Ventilation Manufacturing

From coaxial ducting to high-precision louvers, Punch Tools provides the engineering expertise to produce complex ventilation components with high-volume efficiency.

Custom Precision HVAC Stampings

- Coaxial Ducting Terminations

- Wide Flanges (TDC/TDF components)

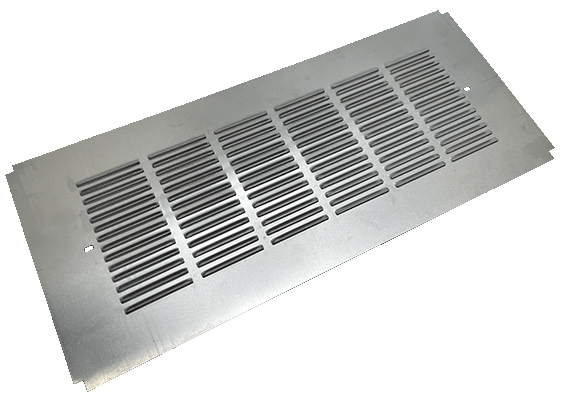

- Vents, Grilles, & Diffuser Plates

- Duct Connectors, Corners & Cleats

- Precision Louvers & Lances

- Hangers & Support Brackets

- Steel Baffles & Gaskets

- Sensor & Thermostat Components

Louver Solutions

Custom Louver Profiles

1" Air Vent Tooling

Ventilation Louvers

Lance & Grill Tooling

Lance Grill Stamping

Airflow Lances

Precision Lance Dies

Specialized Manufacturing Processes

Full Assembly Outsourcing

Venting components often require 20-30 individual pieces. By outsourcing your assembly to our production team, you eliminate the need for large labor and capital commitments, allowing you to focus on your core competencies while we handle the precision fit and finish.

Clinching Tubes to Collars

Clinching is a superior fastening method for light sheet metal. By clinching tubes to collars, we eliminate the need for rivets or drilling, providing a high-quality, airtight fastening that holds up under thermal stress.

Flaring Flanges

Our large 3/4" flared flanges solve critical assembly problems when fastening heavy-duty components. This grounded, simple solution ensures a perfect seal and structural integrity for flue collars and exhaust systems.

Expect more than just hot air.

Email/Call us today to discuss how our experience can deliver cost-effective solutions for your ventilation project.

sales@punchtools.com | 1-800-668-4996

ABOUT US

OUR SERVICES

TOOL & DIE MFG

OUR PRODUCTS

INDUSTRY LIBRARY

11-211 Schoolhouse Street

Coquitlam, BC, Canada. V3K4X9

Telephone

604-521-6444

1-800-668-4996