Shop By Category

Related Links

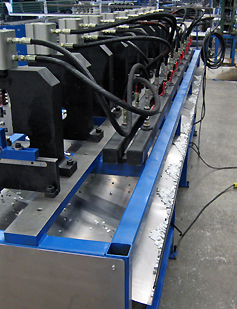

Gang punches designed for common processes boost throughput and efficiency. While batch processing can slow productivity across departments, a high-performance machine, like the ten-station Hydraulic Gang Buster, provides portability, quick setup, and operational efficiency.

Portability

Take the machine to the extrusion rather than moving extrusion to the machine. This approach increases flexibility in plant design and layout. The unit is highly portable and includes the following features:

- Forklift-moveable with a balanced load and a solid, welded 2” square steel tube frame.

- Low centre of gravity for stability during movement.

- Lightweight at 1,000 lbs, compared to a 10,000 lb press brake, making it less top-heavy.

- The ten-station Hydraulic Gang Buster can be relocated quickly across the plant, enabling immediate use in different departments. This maximizes machine utilization and reduces bottlenecks.

Ease of Hookup and Use

- A 240-volt plug connects easily to cable drops around the plant, removing the need for hard wiring and an electrician each time it's moved.

- A large slug tray securely holds slugs for easy cleanup, preventing slipping hazards and keeping the factory floor clean.

- A tethered foot pedal allows the operator to position it efficiently for loading and unloading.

Streamlined Operations

Reduce equipment on the floor and increase productivity with this versatile unit.

- The previous system involved makeshift holes and a mix of drilling and punching techniques, which required complex setups and precise measurements for varied lengths.

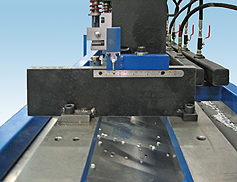

- The Hydraulic Gang Buster simplifies setup with visual alignment for the entire length in one press cycle. Each punch head has a ball valve for adjustable punching speeds.

- Pitch centers are easily adjustable on the mounting table, and back fence settings can be quickly modified.

- Button dies and punch bodies fit directly inside the extrusion legs, providing manufacturing flexibility and meeting productivity targets.

Machine Specifications

- Hydraulic power pack: 240/480 volts (other voltages available upon request).

- Footprint: 144”L x 24”W x 32”H to table top/working height (approximately 48” overall).

- Punching capacity: 10 variable pitch stations at 7 tons each.

- Connections: Flex-hose hydraulic connections.

- Punches and dies: Standard, off-the-shelf components.

- Production rate: Punch cycle time of 5 seconds.

ABOUT US

OUR SERVICES

TOOL & DIE MFG

OUR PRODUCTS

INDUSTRY LIBRARY

PTI Punch Tools Inc.

11-211 Schoolhouse Street

Coquitlam, BC, Canada. V3K4X9

Telephone

604-521-6444

1-800-668-4996

11-211 Schoolhouse Street

Coquitlam, BC, Canada. V3K4X9

Telephone

604-521-6444

1-800-668-4996