Shop By Category

Related Links

Medical Grade Precision Stamping

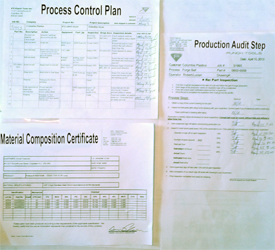

In the medical community, precision is more than a metric—it is a requirement for safety. Through our intensive Process Control Plan, Punch Tools ensures that every surgical component and medical device part reaches its ultimate goal: to improve and save lives.

Surgical-Grade Quality Control

When it comes to medical devices, defect-free production is paramount. We meticulously oversee every stage of production in an environment that fosters diligence and technical efficiency.

Our rigorous standards allow us to maintain tight tolerances for mating components, ensuring that multi-part medical assemblies function with flawless reliability.

The Advantage of Cold Forming

Cold forming is a specialized extrusion process that forces metal at room temperature beyond its elastic limit. Unlike traditional hot forging, this process increases the strength of the metal by aligning the material's internal fibers.

- Mechanical Integrity: Superior internal solidity compared to milling or turning.

- Ultra-Smooth Surfaces: Highly polished internal surfaces essential for medical hygiene.

- Sustainability: Up to 70% less metal waste than subtractive machining.

Technical Capabilities

- CNC Bending & Machining

- Electro-Polishing

- Riveting without Clenching

- Surgical-Grade Tolerances

- Process Control Mapping

Quality Materials

- Medical Grade Stainless Steel

- Medical-Grade Aluminum

- High-Purity Alloys

- Biocompatible Materials

ABOUT US

OUR SERVICES

TOOL & DIE MFG

OUR PRODUCTS

INDUSTRY LIBRARY

11-211 Schoolhouse Street

Coquitlam, BC, Canada. V3K4X9

Telephone

604-521-6444

1-800-668-4996