Shop By Category

Related Links

Aluminum Mullion Hole Punching Machine

Revolutionizing Aluminum Mullion Fabrication: The Power of Punching Over Drilling

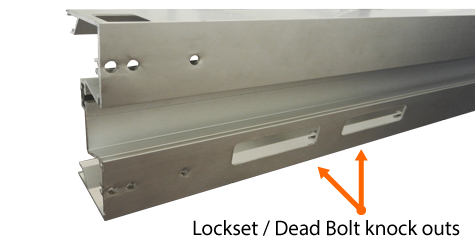

When it comes to creating precise holes in aluminum mullions, the traditional drilling process can be time-consuming and inefficient. Not only does drilling take longer, but it also limits you to only punching holes at the back of the mullion, creating potential gaps in your workflow. However, there’s a faster and more efficient solution — the Aluminum Mullion Hole Punching Machine by Punch Tools.

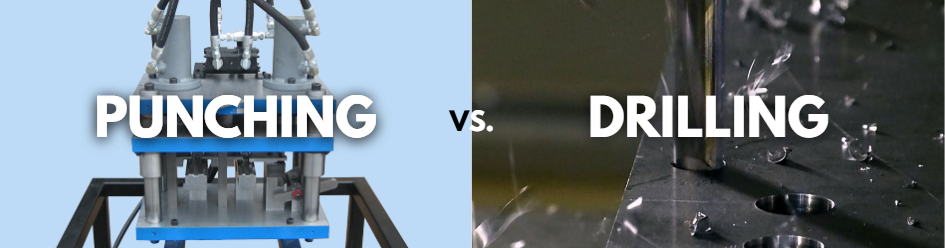

Why Punching is Better Than Drilling Traditional Drilling

Drilling holes in aluminum mullions requires significant time and effort, often limited by accessibility to only certain parts of the mullion. You need to measure, mark, and drill each hole one at a time — all of which can lead to mistakes, inconsistencies, and delays in production.

Punching On the other hand, the Aluminum Mullion Hole Punching Machine makes the entire process faster, easier, and more precise. This machine allows you to punch multiple holes at once, regardless of the part of the mullion or filler, drastically reducing shop fabrication time.

Key Benefits of the Aluminum Mullion Hole Punching Machine:

1. Punches as Many Holes as You Want at Once

With this machine, you can punch multiple holes in one pass, dramatically reducing shop fabrication time. Whether you're working with curtain wall extrusions or any other aluminum profiles, you can punch holes precisely where needed without delays.

2. No More Measuring and Drilling

The process is automated. Simply insert the metal or aluminum parts into the machine, align it against the pre-set flip stop, and hit the start button. The machine will punch as many holes as you need — no measuring or individual drilling required. This ensures and eliminates human error.

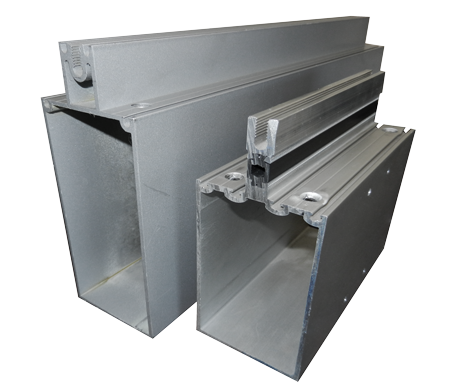

3. Quick and Accurate Setup

The setup is incredibly easy. The machine can be customized with either a single or multi-head configuration, based on your specific requirements. This flexibility allows you to punch holes in various parts of the mullion/filler. We tailor the machine to meet your production needs, making it ideal for both small and high-volume production environments.

4. Reduces Shop Fabrication Time

The ability to punch multiple holes in a single pass speeds up the entire fabrication process. This, combined with the elimination of the need for individual hole measurements and drilling, can significantly lower labor costs and increase overall production speed.

How Does It Work?

The Aluminum Mullion Hole Punching Machine is incredibly user-friendly. Here’s how it works:

- Insert the vertical mullion/filler into the die set.

- Align the mullion/filler against the pre-set flip stop to ensure accurate hole placement.

- Press the start button, and the machine automatically punches holes in the specified locations.

This simple process ensures you get a perfect fit every time, without the risks and inefficiencies of traditional drilling.

Eliminate Common Fabrication Error

A major problem in fabrication is the occurrence of misaligned holes or inaccurate measurements, which can lead to costly errors. With the Aluminum Mullion Hole Punching Machine, you eliminate this issue entirely. The system is designed for precision, ensuring each hole is placed exactly where it’s needed, every time.

Switching from drilling to punching in aluminum mullion fabrication is a game-changer. By using an Aluminum Mullion Hole Punching Machine, you can increase speed, accuracy, and efficiency in your shop, all while eliminating the potential for costly errors. Whether you’re working on a small project or high-volume production, this machine is designed to meet your needs and transform your workflow.

Ready to upgrade your fabrication process? Contact us for additional information about the Aluminum Mullion Hole Punching Machine!

PTI Punch Tools Inc

11-211 Schoolhouse Street

Coquitlam, BC, Canada. V3K4X9

604-521-6444 | 1-800-668-4996

© 2026 PTI Punch Tools Inc. All rights reseved

Powered by Digit Art Designs Ltd.