Shop By Category

Related Links

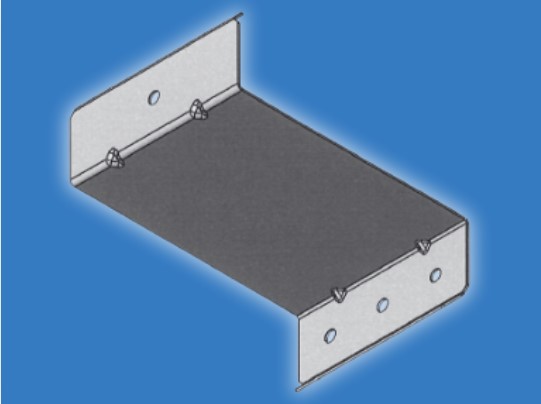

Metal Stamping for Thermal Cladding & Thermal Efficiency System

Metal Stamping Solutions for the Cladding & Building Envelope Industry

Let’s Stamp Out Heat Loss, One Thermal Clip at a Time!

Bring your Thermal Clip to life with reliable and cost-effective manufacturing solutions! We understand the critical role energy efficiency plays in building envelopes. Whether you're a cladding installer, involved in building envelope solutions, or looking to create a custom system, we're here to bring your vision to life!

Have a thermal clip design in mind? Our metal stamping experts are ready to help. We specialize in high-volume stamping of thermal clips with unmatched accuracy, quality, and efficiency — ensuring your manufacturing needs are met on time, every time.

Our Stamping Capabilities

.jpg)

We also specialize in stamping and fabricating a wide range of compatible accessories, such as gaskets and frames.

.jpg)

Stamp your clips with us, offering everything from solid to adjustable designs.

Our precision stamping can help you achieve air- and water-tight building enclosure systems.

Why Choose Punch Tools?

- Eliminate the hassle of part production

- Benefit from the cost efficiency of metal stamping and fabrication

- Focus on winning more projects

Slip Your Clip Like a Boss

As the building industry evolves, our expertise in precision metal stamping helps you stay ahead of the competition. From wall to roof systems, perforated panels, cosmetic louvers, and other building envelope components, we offer tailored solutions to meet your unique needs.

We don't just meet standards — we exceed them, ensuring volumes, quality, and reliability with each part we deliver, so you can trust that your project is always on track and ahead of schedule.

Why Metal Stamping for Thermal Clips?

Utilizing advanced stamping die technology, we ensure your thermal clips exceed the highest standards:

- Low-cost for High-Speed & Large-Volume Production

- Material Versatility: Compatible with various metals

- Customizable Designs: Capable of creating complex shapes and features

Punch Tools for Your Manufacturing Needs

Contact us today to learn how our precision metal stamping services can help improve your building's energy efficiency. Let us work with you to develop tailored solutions that enhance performance and sustainability for your thermal clip and building envelope needs.

Our commitment to excellence ensures that every order is processed with fast lead times and undergoes rigorous quality management procedures.

Are your thermal clips designed to meet the following criteria? Then you have the right metal stamping partner!

- Code-compliant — Insulation continuity to minimize heat loss and energy efficiency in the building envelope.

- National Building Code of Canada & Canada's national energy code (NBC 2020—Division B, Part 3, Part 9 & NECB 2020 Sections 3.2., 4.2., 5.2., 6.2. and 7.2)

- Alberta Building Code (OBC 2012), SB-10 Supplement, NEBC 2017

- BC Building Code: Continuity of Insulation (9.36.2.5) & Thermal Characteristic of Building Assemblies (9.36.2.6 – 9.36.2.8)

- CSA A440: Energy performance standards for fenestration systems.

- International Energy Conservation Code (IECC 2021 R402.4 & C402.5)

The BC Energy Step Code and Zero Carbon Step Code (2024) establish guidelines for energy-efficient building practices in British Columbia.

- As of May 2023, most new buildings must be 20% more energy efficient than those under previous Step Code requirements. The Zero Carbon Step Code allows jurisdictions to incentivize or require low- or zero-carbon buildings. Together, these codes position BC to achieve zero-carbon new construction by 2030 and net-zero energy-ready performance by 2032.

- These commitments align with BC’s 2030 greenhouse gas reduction targets and its 2050 net-zero goal. Buildings are now more airtight, and supply chains provide energy-efficient materials like high-performance windows and modern building envelopes. These standards apply to various building types, including houses, small buildings, quadplexes, rowhomes, low-rise MURB (multi-unit residential buildings), and large, complex buildings.

- A high-performance building envelope regulates heat and airflow, reducing reliance on mechanical systems. Continuous exterior insulation minimizes heat loss, while reducing thermal bridges—areas of higher heat transfer—enhances efficiency. This is achieved through specialized framing or continuous insulation. Thermal clips further improve performance by supporting cladding while maintaining continuous insulation, reducing thermal bridging, and optimizing envelope efficiency. Good examples of continuous insulation include all-electric and passive house designs, which further promote energy efficiency and sustainability.

- Beyond energy efficiency, high-performance envelopes contribute to superior airtightness, enhanced thermal performance, and "cool" wall benefits, improving a building’s overall sustainability.

By adopting these strategies, builders can significantly reduce energy consumption and emissions, supporting BC’s path to net zero.

Click to visit our Metal Stamping page for Construction & OEM Industries.

Punch Tools

Phone: 1-800-668-4996

Email: sales@punchtools.com

Website: www.punchtools.com

Excellence in Custom Metal Stamping Solutions

PTI Punch Tools Inc

11-211 Schoolhouse Street

Coquitlam, BC, Canada. V3K4X9

604-521-6444 | 1-800-668-4996

© 2026 PTI Punch Tools Inc. All rights reseved

Powered by Digit Art Designs Ltd.