Shop By Category

Related Links

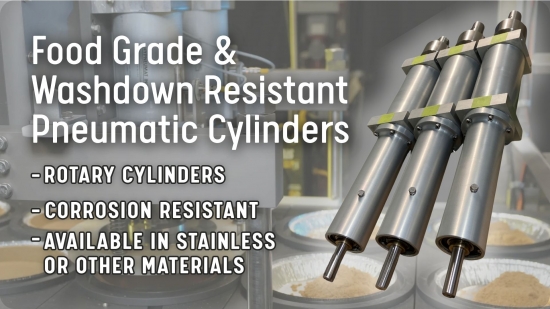

Food Grade and Washdown Resistant Pneumatic Cylinders

Stop the Rust: Why Washdown-Resistant Rotary Pneumatics are a Game Changer for Food & Beverage

In the high-pressure environment of food and beverage manufacturing, equipment reliability isn’t just about performance—it’s about hygiene and durability. Standard pneumatic cylinders often fall victim to the harsh chemicals and constant moisture of daily cleaning cycles, leading to rust, contamination, and costly downtime.

At Punch Tools, we’ve engineered a solution: our Food Grade & Washdown Resistant 360° Rotary Pneumatic Cylinders.

Engineered for the "Splash Zone"

Our rotary cylinders are specifically designed for safe, reliable operation in environments where cleanliness is non-negotiable. Key features include:

-

Premium Materials: Constructed from 304 Stainless Steel and Anodized Aluminum to eliminate the risk of corrosion.

-

360° Precision: These cylinders provide full 360-degree rotation, offering the flexibility and precision needed for complex automated tasks.

-

Safety First: They are corrosion-resistant and fully safe for use in food contact zones.

-

Fully Pneumatic: Our designs are 100% pneumatic, ensuring a food-friendly operation without the risks associated with other power sources.

Custom Solutions for Your Application

We know that no two production lines are the same. That is why we offer rapid custom manufacturing to meet your exact application needs.

-

Custom Stroke Options: Whether you need the 6-stroke design shown in our latest demo or a unique configuration, we build to your specs.

-

Versatile Integration: Ideal for sorting, packaging, and assembly lines within the food and beverage industry.

Ready to Upgrade Your Line?

Don’t let rusting cylinders slow down your production or compromise your safety standards.

Contact Punch Tools today for a quote on our washdown-resistant solutions:

-

Phone: +1 (800) 668 - 4996

-

Email: sales@punchtools.com

PTI Punch Tools Inc

11-211 Schoolhouse Street

Coquitlam, BC, Canada. V3K4X9

604-521-6444 | 1-800-668-4996

© 2026 PTI Punch Tools Inc. All rights reseved

Powered by Digit Art Designs Ltd.